Installation Guide

Introduction

“Simplify the supply chain, improve product quality, carry no debt, operate on low margins, lower costs with no a no frills marketing strategy. Then bring this value to our customers so they can add what would have been lost profit into the value of their own home or business. Give the power back to the customer. Completely disrupt what has been well over half a century of inefficient supply to the end user!” David Shearn 2009.

A lot of academics and Business schools would say this paragraph above is impossible. I believe and please any English teacher or journalist correct me is an oxymoron. You cannot offer all of this without impacting one aspect. So you cannot have Low Price, Quality, Value, Quick Shipping and Service. One must be surrendered to achieve the others. But academics also thought Fedex Paper by George W Smith at Yale in 1965 was unrealistic as well. I believe this model is possible but it takes working together with the customer. Particularly on the natural stone. All we need customers to do is read. Read the Terms of Sale and our FAQ’s and particularly the top 10 mistakes people make. If we work together the impossible is possible. But it really does need the final step our customers. We have gone to the trouble of removing every conceivable cost from the supply chain (even debt, debt is a cost to many businesses we have none and that cost is not passed on through our products) but we need our customers help on the last step, maybe you have a counter you are matching Carrara to, or need a particular look, then these are things we should talk about. (We do not know the look of the countertop you purchased if we are not sent a picture, or the look of marble you want 200 square feet of without discussion. We cannot read minds, believe me if we could we would probably be doing something else 🙂

If we work together instead of viewing a bathroom remodel as a “going to loose 30%” (as the industry has created and perpetuated) to a “gain 30% on the value of your home”. Together we can change an industry from a consumers loss to a consumers gain in property value. The impact on America would be incredible. A home underwater by $5K could be above water. Risk of foreclosure lowers across the country. So we work hard everyday to make this happen. We do not have to. We could charge the same as the “Industry” and perpetuate their false narrative to make larger profits at the expense of consumers. But in our minds that is not fair. In return we expect fairness. There is a 5% acceptable damage policy. Read it. If you do not agree, then do not buy. Pay the $50-$70 a square foot from a local retailer. There has to be some give and take to make this happen.

I never could understand an industry that was created around ‘Buy our product’ have it installed and once you have done so do not expect 100% return on your effort and investment. Yet people have believed this for multiple decades. We want to change this and we will give it a go. But we need your help to read, understand and communicate.

#1 STONE INSTALLATION GUIDE

The Builder Depot Stone Mosaics may be used for interior and exterior wall and floor applications and is suitable for both residential and commercial use.

Please note:

Your contractor is not likely the person installing the tile. If you have opted for Carrara or any natural Stone it is not Ceramic Tile and requires someone with specific training from The MIA (Marble Institute of America), look for Natural Stone installers and someone who can show you their work, specifically white marble.

Think of yourself as running a company. You are looking for a book keeper. You would not hire a fork truck driver for this position. The fork truck driver may want the job, may want the job and the hourly rate the book keeper earns. But he has no experience, has never done this job before. You would simply not hire him.

The same applies to whomever you hire for your installation of your bathroom, backsplash, etc. Qualifications are the key. Today social media is everything a fully qualified installer will have an active Instagram or Facebook account. They will be really, really proud of every single job they do. Take a look as this installer and his work. He uses our products quite often. It is not just the fact that he is fully qualified which is excellent. It is his level of detail and “Pride of work”. So proud of everything he does he records it in a timeline on both Facebook and Instagram. Anyone annoyed with the quality of his work could easily comment back. But there is nothing but praise.

This post gives good information on the skills levels and requirements here. It requires special handling, just because someone can drive a car does not mean they can fly a plane. You have saved on the product. But you cannot save on the install. There is only one way to do it and that is doing it right. Or it just gets very messy and expensive.

The professionals of the Natural Stone Installation world have a saying. “You think the price of hiring a professional is expensive. Wait until you realize the cost of not.” Remember ultimately we are dealing with water. You do not want mistakes.

Now for some intel for you, the consumer. So you can quickly and easily spot a fraudster, someone who is not certified:

Dry run first. You lay it out before sticking anything down. You organize the veining to ensure it is not grouped any rouge tiles or tiles you simply do not like the veining of you discard. Tile is art. What you find attractive others will not just as a different grout color can completely change a look so can how the veining and how heavily veined tiles are used or not used in the design changes the look. Your installer should lay out a sample area and get your input. Or you lay out a sample area and ask him to replicate. It depends on the quality and competence of the installer or craftsman you have hired.

If your installer just starts to go from box to box installing right away. Fire Him. Say “Your Fired!”. That is not how you install marble. You lay it out. You step back. You move pieces around. You step back. Look again. Remove a piece. Add in another piece. Throw away that piece add in this piece. You are creating a “Picture” you are the artist and only YOU know the picture YOU want.

Now the fraudster has been asked to leave. Go online and find a certified installer. If it is marble you will want certifications in marble. You will want some evidence on social media that he has done this before. Why social media? Because he or she is proud of their work. So proud they post pictures of it. If they do not ask yourself why!

(Now back to you the consumer) You are creating a perfect picture. You need to have a qualified marble installer (think Marble Institute of America qualified) for your local area. This person will know if the marble should be pre-sealed before grouting (ask this question…. then if you get a blank look, you have not hired the correct person). The lighter the marble the more the challenge and as always that is what a lot of people look for. The Venato is a lighter stone, grout that without pre-sealing and even a light grout can change its color, the moisture from the grout will soak into the stone. Why? Because it is not sealed. Will it dry out and go back? We are not installers. You need to actually see who is doing the install. I assure you your architect and your contractor will not be. So who are they using? Get involved. Otherwise you will be calling us about color changes and then you will be very sad 😦

Finally please remember marble is millions of years old. If has been rained on snowed on for millions of years. It has been cut into blocks. It has been left outside in the elements for a few more years than you have had owned it, it was here before your were on this planet. We have then cut it finally and boxed it. It is perfect (almost). Only now in what as a percentage of time (for this great stone) is but a blink of an eye of its lifetime has this changed color. It is not because of the stone. It is most likely any number of reasons.

The most common we have found is “it was not sealed and the shampoo or chemicals in your shower cause this” or “it was sealed and then cleaned with a product that removed the sealer and then exposed to your soaps and other liquids” or “cleaned by our cleaners with who knows what, this removed the sealer and guess what!”. You are now the guardian of a product that is unique and millions of years old. No one will care about this more than you! Read everything you can, even a blog like this is helpful.

Most important please read one to thirteen:

- Be involved in the project. Do not just pass this to an unqualified natural stone tile installer and say “tile that 200 square foot bathroom, I am off out of town” and as you walk away say “the tile is in a sealed crate in the garage”. This is a potential disaster. You have to check the tile. You have to check the installer is qualified.

- This is for the person installing (and please experts do not go duh! That’s obvious). When the tile or mosaic is shipped to you do not start with the box on the top and start laying down the tile box to box. There may be variation in the tile color, you may have inadvertently got a mixed lot (it happens the Italians are only human and so are we). You definitely do not want half a floor of one shade and then half a floor of another shade and not realize this until it is installed. If your natural stone installer is not certified and if left to his/her own devises they will just install as fast as possible. He will not look at the stone. Only once it is done and you come back home would you realize the error. He/She will not! (You would not give your car mechanic $20K-$30K and say go ahead and buy me a car I am going on vacation, just park it in the garage for me. What do you think you would find in your Garage?) So do not leave a person with no design knowledge in charge of installing your bathroom on their own.

- We put windows on some of the boxes the mosaic, please at the very least look at the window of each box – verify the stone all looks the same, open others. The box will be the same shape Hexagon will look different to Basketweave, but if you accidentally received a mixed product looking at the window or opening the box will show this easily. Contact us, we will replace the tile and correct the mistake. It happens maybe only 1% of the time. Again do not assume, we have seen installations of half Basketweave and Half Hexagon and the installer just (didn’t think) believed this is what the customer wanted.

- Please be involved, you need to check the product for suitability of installation. YOU! The person that ordered it! Once you stick it to the ground it is yours.

- Do not contact us after you have missed steps 1 through 4 and say “you need to fix this.” and “Look what happened while I was on vacation or while I was at my Summer House” I know this is a nation that has no personal responsibility anymore, but we hope our customers are different, please, please, please be different and be involved. If you have no desire to be involved and have it shipped to your “other” home and installed by your “gardener” who has seen a few HGTV shows and thinks he can do it. Then please do not buy from us. This is not practical, it is unfair to you and us. I am sure many kids have flown flight simulation games on their game consoles, but I am pretty sure you would not want that teen just having a go and trying to see if they can stick that landing, with your family on board a real plane.

- Our prices are low. We cannot hire QC person to check every tile we own and ship. If you do not want to follow steps 1-4 then please let us know. We will hire a professional tile installer for a day. He will be certified from the Tile Association. He will check through the product for you. We can send you a $2,000 and up (depending on order size) PayPal invoice for his time (we know you are not going to do this, you would not be online looking for tile if you were – we are just trying to make the same point over and over again ‘check before you install’). He will do this job for you. Or like 99.9% of us, save the money and spend an hour checking it yourself.

- Once you install the tile it is yours. You cannot come back after you did not follow the steps above and ask us to, 1) Ship you free tile to replace the mistake, 2) Pay for the installer to correct his mistake.

- Please be involved. This is your Bathroom.

- Please check before you install.

- Seal before you grout follow the sealer instructions, seal after you grout. Ask your installer questions, check his knowledge, learn from DuPont’s Bullet Proof sealer guide. Do not hire a ceramic installer. Yes he will be the cheapest, check references he should at the very least have installed marble for many years and have some qualification from the Marble Institute of America (you have saved a fortune buy ordering online, the only part you cannot save on is the install) they will not do it correctly.

- No natural stone is pre-sealed. It needs to be sealed. This is a handy tip at the end of the job INSIST the installer shows you how to seal correctly because in 4-5 years you will have to do it yourself. This does two things #1. It does not offend him like you are a crazy micro-manager (but you secretly are) and #2. It ensures he does a good job. This is the part they skip, you cannot tell, you cannot see it. Be there for the final step of sealing. Do not skimp and by a cheap sealer.

- This is all obvious to anyone that is accredited from the Institute of Marble. Check your installers qualifications.

- Read steps 1 through 12 again. Thank you!!

If this has happened and now you are reading this, we are sorry. You are the unlucky one. Please take a DEEP BREATH. Your reaction maybe anger. It has happened, hiring that cheap installer, not having a designer supervise the project while you were on vacation, and not checking references did not pay off – now lets fix it! Your installer is just about to get a crash course in installing Carrara and the importance of checking prior to installing. He should be grateful. You are his college, his on the job training! He should be paying you for the knowledge you are now about to pass onto him.

We are here to help and we will help to fix the problem. Clearly it is easier to fix if you catch it prior to sticking it to the floor and all we have to do is UPS two boxes of replacement mosaics that match (that would be amateur easy!). But if you did leave the installer to it and the lot was mixed we will try and fix it.

We will have to work together. You may have to send us a sample of the tile you want. We go through crates, match it up (if possible). You then place an order (yes you have to pay for the replacement product and shipping as you have nothing to return, you installed it) for two boxes perhaps $100.00+ shipping which I would take from the installers payment (he messed it up, as I am sure he told you he was competent and great at Carrara installation – only now do you find out he was not upfront). Then bingo! Fixed!

We will not just say tough luck. Why did you do that? We are here to help!

I know this was very candid and some people will be offended by the honesty, tone, etc. I apologize for any hurt feelings that was/is never our intention. I can only imagine the people most offended are reading this “after-the-fact”. Our intention is to just labor the point that you need to be careful, natural stone is just not a chuck it up on the wall and be done in a day project. It requires planning, dry laying and never installing box to box. You want to make sure that what is stuck down looks the way you want it to you are creating art and no installer will are about that, HGTV has an installer and a designer to insure it looks perfect, you will have to be the HGTV designer and move tiles around to ensure the veining looks awesome and is in the correct places before being stuck to the floor or wall. You will have to move things around, number the back of the tiles and the wall, so the numbers are matched and you get the look you want. Prepare to dig in, get lots of coffee and get involved.

Prepare for Installation

- Set mosaics on a substrate that is rated to hold natural stone. This will include cement backer boards, concrete masonry units, brick/masonry, exterior grade plywood, traditional mud beds, etc. Consult a professional builder for rating requirements before starting the project.

- Insure the framing is structurally sound and up to code.

- Be sure the entire surface is level before installation.

- All surfaces must be sound, clean, and free of oil, waxes, frost, curing agents, form release agents and any other bond inhibiting contaminants. After the surface is completely clean, inspect the surface for any dips or bumps. Make all repairs necessary to make the surface level and smooth.

- Before you begin, insure that whatever type of setting materials used are rated to hold the types of stone mosaic being used. Be sure to use non-staining setting materials and follow the manufacturer’s instructions to make it ready to be troweled onto the surface.

- Shuffle the tiles from different boxes so variations in color are distributed throughout the installation.

Please note: The buyer is responsible for both inspection and acceptance of our materials prior to installation. The buyer is also responsible for determining whether this product is appropriate for a particular installation. Use of the tile constitutes full acceptance. No adjustments will be made after the tile has been installed.

Set Up The Builder Depot Mosaic:

- Using no larger than a 1/4” x 1/4” inch “V” notched trowel (a 3/16 “V” notch is usually perfect) or one suggested for the setting materials used, trowel out enough mortar or adhesive to cover the area to set the first few sections. When troweling the mortar, be sure that it is spread evenly. Thick spots will result in mortar bleeding up through the seams. Should this occur, mortar will need to be removed from the seams before grouting. Thin spots will result in stone mosaics not sticking at all. For best adhesion, cover the back of each individual or sheet of tile with a thin layer of mortar using the trowel.

- Carefully place the first two to four sections of tile into place. If product is mesh backed, place the tile mesh-side down into the setting material. Using a level surface such as a wooden block and a rubber mallet, tap the sections into the setting material, avoid the outside edges adjacent to the next sections. Next, press another section into the setting material, making sure to match the width of the established grout lines. Doing so will prevent the seams from showing. Tap again with your flat level surface, this time pressing down on the seams between sections (this avoids “cupping”) but again, avoiding the outside abutting edges (except for the edges that are against the outside wall or threshold).

- Repeat this process for the next few sections, periodically examining the installation. If the seams are undetectable, the job has been done well. Seams are created by gaps in section placement, uneven (height) pieces along the edge of the seam, and stone mosaic not lining up within a section. The seams will need to be re-worked between the sections as necessary to make them undetectable. To rework seams reset pieces on the seam to blend evenly. Periodically use your level to insure tile height is consistent. Repeat steps until the stone tiles are set and seamless. Follow the instructions on the setting material package; do not walk on the surface of the tile for 24 to 36 hours depending on the type of setting materials used.

Grout The Builder Depot Mosaic:

- Apply a coat of quality penetrating sealer before grouting. Grouting a porous stone product without sealing may cause the stone to wick up the grout making clean-up difficult. Please note; sealers for natural stone are available through local hardware stores and tile retailers. Do not use a top coat, as it will change the color of the stone. Allow sealer to dry according to the manufacturer’s directions.

- Choose a grout color appropriate for the installation. For a seamless look, use a complimentary color. Mix grout according to manufacturer’s directions.

- Grout openings between tiles and sheets.

- Clean the joints with a damp sponge taking care not to remove too much grout. A powder residue will appear. Buff this with a soft dry cloth.

- After grouting, protect area from foot traffic and water exposure for at least 72 hours.

- Once the stone is 100% haze-free, clean once more with a vacuum. Apply the final coats of sealer following the manufacturer’s directions.

Please Note: Not all adhesives, cleaners, grouts and sealers are not equally suitable for all types of tiles. Check with a flooring and tile specialist for specific recommendation on installation of all Natural Stone Collections.

INSTALLING CARRARA VENATO SUBWAY TILE (HONED)

We worked with Brittany AKA Pretty Handy Girl (Blog) with her Kitchen Backsplash. It is no small site with over 400,000 page views a month and 25,000 Facebook fans. So without our knowledge she ordered samples from us and others. We were chuffed to bits she decided on our product (Carrara Venato 3×6″) and here we have some greatly useful information on Carrara Venato installation.

Note: Do not use fine sandpaper or any scratching material on polished tiles. Works only with honed.

INSTALLING CARRARA VENATO 2″ OCTAGON (POLISHED)

We provided the product for this fabulous DIY adventure blog thehandmadehome.net. The product they chose to install on their bathroom floor was our 2″ Carrara Venato Octagon mosaic tile. This post 10 tips for laying tile provides a great ten step guide to installing mosaic tile. For the consumer information is power. Most likely you are hiring a contractor to do this installation do not assume anything. Gain knowledge and then question your installer. You need to have knowledge so you can determine that he has the skills to do the job and this post helps.

10 tips for laying Carrara Venato 2″ Octagon Mosaic Tile

10 tips for laying Carrara Venato 2″ Octagon Mosaic Tile

TIPS FOR TILING A BATHROOM WITH CARRARA MARBLE

Karah at thespacebetweenblog installed our Carrara Bianco marble in her Bathroom. This remodel provides some excellent tips for a tiling a bathroom. Even if it is not you that is doing the work, when it comes to contractors or tilers knowledge is power. So we want to provide our customers with as much ‘Power’ as possible :). Enjoy!

Tips for tiling a Bathroom with Carrara Bianco Marble Tiles

Tips for tiling a Bathroom with Carrara Bianco Marble Tiles

#2 GLASS INSTALLATION GUIDE

Glass Tiles may be used for interior and exterior wall and in some cases floor applications. Brilliant Glass tiles are manufactured to satisfy industry specifications for glazed wall tile and are recommended for residential and commercial use. Brilliant Glass tiles are impervious to water and stains, highly resistant to chemical attack, resistant to fading and discoloration. Variations in color, shade and size are inherent in all fired glass products. The glass tiles should not be exposed to high abrasion, or extremely heavy impact.

Our Glass Tile (our glass tile, not all some is just painted and cured – this is not a good way or good product to use, it is likely to peal and delaminate the backing, whereas our glass tile is kiln fired. You really want kiln fired glass tile) is Kiln Fired at about 1,200F to 1,500F. The temperature can vary, barometric pressures vary. This can create some slight changes in color from lot to lot. It is essentially that the glass tile is dry laid before installing. Make sure you have enough is another reason, you do not want to have to order more and we have to take it from another lot where it was Kiln Fired in the Winter when your 90% installed tile was Kiln Fired in the Summer. Dry lay the installation. Make sure it matches before you stick it to the wall.

Be clear with the contractor that you want to sign off on the dry lay before it is stuck to the wall so any variation is noted and accepted then. Please do not email it after it is stuck to the wall saying “Look it does not match”. We can fix this easily before you have stuck it to the wall. Rather like not liking your steak, do not clean the plate and then say “I did not like that”, or keeping with Home Improvement “Use all the paint and then want to return the empty cans”. You would have checked first. This has to be done with Natural Stone but also with glass tiles.

The following recommendations comply with the TCNA (Tile Council of North America) Handbook Guidelines.

Recommended Substrates

Well cured mortar beds-ANSI A108.1B (cured a minimum of 7 days). Cementitious backer units (CBU)-ANSI A118.9 (Note: An ANSI A108A-2.1.8 membrane is required behind all CBU installations in wet areas. Concrete slabs (on grade) cured for 28 days minimum. Gypsum board (dry areas only)-ASTM C1396 or ASTM C1396M-04.

Note: Directly bonding glass tiles to wood substrates is not recommended. All surfaces to receive tile shall be left clean and free of dust, oil, grease, paint, tar, wax, curing agent, primer, sealer, adhesive residue, form release agent or any other deleterious substance and debris which may prevent or reduce adhesion.

Glass tile expands and contracts more than ceramic and porcelain tile. This movement needs to be accommodated in the installation, particularly where temperature changes may occur. Be sure to use caulked joints on all inside corners where walls intersect, especially in showers, backsplashes and cook top areas. This recommendation is standard installation procedure though frequently ignored with ceramic tile. It is critical with Glass tile installation.

Setting Materials

We recommend any high grade flexible mortar system (latex modified) as setting material for glass tiles. For grouts, a premium polymer-modified unsanded grout for joints from 1/16” (1.5mm) to 1/8” (3mm) wide. For grout lines larger than 1/8” (3mm) wide use a sanded grout.

Installation

Note: If the product has a directional grain, it will be indicated on the mounting surface with an arrow. It is important to make sure that all arrows are facing in the same direction when installing this product.

Paper-front Mounted Mosaic Tiles

- Mix setting materials according to manufacturers’ instructions.

- Apply setting materials to the substrate using the notched side of a 3/16” x 5/32” x 3/16” V-notched trowel.

- Using the flat side of the trowel, smooth out all ridges to achieve a consistent, and voidless coverage.

- Apply glass mosaics to troweled setting material with the PAPER-SIDE FACING THE INSTALLER.

Mesh-mounted Mosaic Tiles

- Mix setting materials according to manufacturer’s instructions.

- Apply setting materials to the substrate using the notched side of a 3/16” x 5/32” x 3/16” V-notched trowel.

- Using the flat side of the trowel, smooth out all ridges to achieve a consistent, even 1/8” thick coverage.

- Apply glass mosaics sheets, MESH-SIDE DOWN, into the freshly troweled setting material.

Installation Guide – Glass Tiles Individual Glass Tiles

- Mix setting materials according to manufacturer’s instructions.

- Use a 3/16” square-notched trowel to apply setting materials.

- Smooth the trowel ridges in the setting material using the flat edge of the trowel before setting the tile or the setting material ridges may show through.

- Additionally, each piece should be “back-buttered” with a thin, continuous layer of the setting material.

- After tile application, use a rubber float or equivalent tool, gently press the tile into the adhesive and flatten sheets to each other to insure complete contact. Do not push the sheets too deeply into the setting materials, as this will cause the setting materials to ooze up between the spaces in the tile.

- Adjust tile sheets for correct alignment and even spacing between sheets. Do not allow setting material to dry or skin over before completing this process.

General Installation for all tiles

- Allow setting materials sufficient time to set (see manufacturer’s instructions).

- For Paper-mounted mosaics, use a wet sponge and apply warm water to the paper to soften the glue, allowing the paper to release. Avoid using too much water. Gently peel back the paper.

- Clean all excess setting materials with a damp sponge. Clean all excess setting materials that may have remained on the tile surface. Wipe away any haze that may have remained behind.

- After 24 hours, mix grout, following manufacturer’s instructions.

- Grout openings between tiles.

- Clean all excess grout immediately with a damp sponge.

- Polish off any remaining haze with a dry cloth or towel.

- After grouting, protect area from light foot traffic and light water exposure for at least 72 hours. Protect area from heavy traffic and regular use for at least 7 days.

Cutting & Drilling

We highly recommend that cuts be made with a wet saw and a NEW diamond rimmed blade designed SPECIFICALLY to cut glass (we recommend the MK-215GL). Slowly push the tile into the blade. Pushing too hard or cutting too fast may cause the glass to chip. Ceramic tile blades are NOT recommended; their cuts are too coarse and tend to chip tile surface of the glass. To finish the edge, smooth with a diamond hand pad, tile blade or dressing stone.

Should you choose to use a ceramic or a dull worn blade, to prevent chipping, score the enameled or back side of the tile before cutting. Doing so will relieve surface tension enough to cut the tile without too much chipping.

Drilling holes through glass tile can be accomplished with a diamond core bit using a drill with low speed (250 to 300 rpm). Continually misting the tile and drill bit during cutting is imperative to prevent glass from cracking. If partitions or fixtures are to be attached with anchoring bolts, drill hole 1/8” larger to avoid stress transfer to the tile. If tiles have not been installed, drilling from both sides will minimize chipping and cracking.

#3 METAL MOSAIC INSTALLATION GUIDE:

Before starting sometimes it is nice to see our metal installed buy someone else this is a nice blog to view.

1. Stainless steel penny rounds, brick metal and square metal mosaics are made of a metal capping glued onto a porcelain tile body.

2. Sheffield has a grade 304 stainless steel finish. The different colors of stainless are produced by an anodizing process. Colors are V1 in shading. Brushed and stippled metal will be installed randomly on the sheet from the factory, in reference to the direction of the texture. This will give the appearance of different shades, and adds to the character of the product.

3. The glue used to bond the metal to the porcelain base is German “Henkel” contact adhesive. It is temperature resistant to 158 degrees Fahrenheit, water resistant, and resistant to diluted acids and alkaline.

4. Penny Round copper may be installed on interior wall areas, in wet or dry locations (such as a shower wall or kitchen backsplash). It may not be installed on floors. Through oxidization, all copper will patina (darken or turn dark green).

5. Copper should not be used in steam showers, submerged areas, or exterior applications.

6. Stainless steel mosaics should not be used in steam showers or submerged areas, but can be used in frost-free exterior applications. Both stainless and copper can scratch and dent.

7. Make sure all product is inspected by the end user before installing to avoid any issues. No refunds or adjustments of any kind will be made by www.thebuilderdepot.com after the product is installed. The installer is responsible for installing the correct material. Use constitutes acceptance.

8. To cut, use a tile wet saw with a diamond blade designed for cutting porcelain. Target, Pearl, MK, and many other blade manufacturers make blades for porcelain. Always cut with the metal side up. It may be necessary to debur the edge of the metal with a rub stone or fine file. Always wear eye protection.

Suggested Installation Method

1. Always use a licensed contractor.

2. Always confirm in person with the end user / specifier that the product being installed is the correct product before installing it, and is suitable for the project.

3. Always inspect the product for unintended flaws that are not part of the fashion or style of the product. Do not install defective or damaged product. If there is a question about the quality of the product, contact your supplier before proceeding.

4. Make sure the substrate is suitable for stainless steel metal mosaic. Choose and follow the best technique for your project. See TCNA handbook, page 10 and all pages pertaining to substrate preparation.

5. TCNA handbook, page 10. And all pages pertaining to substrate preparation. ANSI A108.1B, A108A2.1.8, C1396, C1396M-04 Make sure crack isolation membranes and water proofing membranes are considered for your type of installation where necessary.

TCNA handbook, page 9, 10, ANSI a118.10, A108.12

6. The metal mosaic may expand and contract differently than adjacent tile. Make sure expansion joints and movement joints are considered and used when necessary. Keep this product over six inches away from an open flame. Areas of concern would be steam rooms, fireplace surrounds, and backsplashes behind cook tops. Extra soft joints may be required in these high heat areas. Use a soft (caulking) joint between the metal and any other material in a continuous installation. Use a soft joint where two different planes come together. Use a soft joint every six feet in a continuous run, or according to the TCNA handbook. Use a soft joint where the metal abuts to plumbing fixtures, cabinets, counter tops, window or door moldings, and bath tubs in accordance with the TCNA handbook. TCNA handbook, page 8, 9, 68, 69, and EJ171-05.

7. Use a flexible modified white thin-set mortar that meets or exceeds ANSI 118.4 (a flexible acrylic mortar system such as those from Mapei, Laticrete, TEC, Customs, C-Cure, Siena, or equivalent). Follow the manufacturer’s instructions. Organic Mastic and Epoxy are not recommended for Penny Rounds.

8. Use the correct size notch trowel depending on the size of the product and your desired results. In most cases a 5/32 x 5/32 v-notch trowel will be used. Do not allow the white thin-set to rise up in the joints. Make sure you achieve full contact between the back of the tile and thin-set; you may use a clean grout float to embed the metal.

9. Allow the thin-set to cure according to the manufacturer’s instructions.

10. Use a modified grout. Grout with flexing capabilities or a flexible additive is preferred.

11. Non-sanded grout is highly recommended. Be careful not to scratch the metal with the non-sanded grout. The colored metals can be damaged and the color removed by over-rubbing during the grouting process. Perform a test to see if the grout will scratch the metal on a loose piece before proceeding with the installation.

12. Epoxy grouts and pre-mixed grouts are not recommended with copper or stainless steel because they can chemically damage the surface. This reaction can also stain the grout.

13. Read and follow all manufacturer’s instructions on the grout.

14. Buff and cure the grout according to the grout manufacturer’s instructions. Sealing the grout is optional, follow all instructions regarding sealing. The metal mosaic does not require sealing and is non-absorbent.

Care and Maintenance

Regular cleaning with a neutral tile cleaner and a soft cloth or sponge is recommended. Use cleaning products that don’t leave a residue behind. Rinse with a soft wet cloth. Buff dry with a soft cloth. Do not use acids or cleaners containing acids or oils, corrosive chemicals, or abrasive cleaners. Do not use ammonia based cleaners on copper.

Care and Maintenance for Borders

Regular cleaning with a neutral tile or stone cleaner is recommended. This will also clean the glass and metal components in some of these products. Use cleaning products that don’t leave a residue behind. Rinse with a soft wet cloth. Buff dry with a soft cloth. Do not use acids or cleaners containing acids or oils, corrosive chemicals, or abrasive cleaners. Do not use ammonia based cleaners on copper.

Copper

Copper will patina (darken) over time. Topical coatings usually don’t stick to metal products. To slow the aging process, if desired, one can apply a light coat of a high quality Carnauba auto paste wax to the surface of the copper, when dry, buff off. Make sure there are no abrasives in the wax. Abrasives are very common in auto waxes. Waxing will reduce the exposure to air and thus slow (not eliminate) the aging process as long as the wax is not removed. Be careful not to get the wax in the grout. It could discolor the grout.

Although very tough, all metals can scratch or dent, use common sense when choosing the installed location.Looking for a Blog to see our metal installed this is a nice one to view.

Cutting Stainless Steel Metal Mosaic Tile

In a lot of cases due to the small size of the individual metal tiles they can be cut away or taken off the mosaic mesh and used as individual pieces to fit the area exactly. However when the fit is not exact cutting may be necessary.

Fortunately Sheffield Steel metal mosaic tiles are not solid metal, fortunate for the installer cutting and fortunate for us shipping and making the cutting of stainless steel mosaic tile far less challenging. This is due to the fact that that Earthworks metal stainless steel tiles are actually porcelain tiles covered with a 1-2mm stainless steel cap. If the entire tile was solid metal cutting with regular tools would be impossible the product difficult to ship and expensive to make.

The best method is to use a motorized wet saw. Because the tiles are so thin, you can often get by with a low grade, low cost tile saw available at most big box stores. These saws typically retail around $80.00. Many big box stores and tool rental company’s also rent tile saws, so if you are doing this as a one off project, you might consider renting a tile saw for a day to get your job done. However please cautious tile saws can be very dangerous with diamond tipped blades these saws are extremely sharp. Earthworks metal mosaic tiles pieces can be small as small as 1×1” for the small square mosaic so you must have enough confidence and skill to cut the tiny pieces without causes yourself serious injury.

The other option is to use a ceramic tile hand saw, also available at most local big box or tile stores. It is important to mention however that there is one tool that will likely not work for cutting metal tile, and that is a scoring tool or the scoring technique that is typically used for cutting porcelain and ceramic. This tool works on the basis of scoring the relatively soft surface of porcelain or ceramic then using force on two points to ‘snap’ along the scored edge, however metal capped tiles don’t take well to scoring or simply snapping so this method will not work.

If you do not feel comfortable with these sharp, potentially harmful tools it is best to call a professional to make the final cuts required to finish your tile job.

We hope this will give the installer an avenue to become and stay educated with the most current recommendations. Please refer to the TCNA hand book regularly because it is revised each year and techniques can change. Our goal is to have trouble-free long lasting installations that can be enjoyed for a lifetime. Use constitutes acceptance, there will be no credits, refunds, cash settlements, and etc. made after the product is installed regardless of the circumstances. The TCNA website is www.tileusa.com

Finally… How do I finish the edge?

You can finish the edge of your metal tile with metal/stainless steel edging. These are generally associated with ceramic metal edge pieces. If you go onto Google and search “metal edge L finishing piece” you will get a plethora of options the #1 choice by professionals is the Schluter system. You just butt your tile up to these pieces below, they come in all sorts of shapes (look a the ‘S’ shape….Wow!” For those that like a challenge 🙂

You can also consider the metal edger that we sell, cut into strips it can be another good option in particular to match or one of our trim options or pencil.

#4 INSTALLING LARGE FORMAT TILES

Large format tiles come in a wide range of colors and designs, making them suitable for a variety of design aesthetics. Large format tile is considered to be square or rectangular tiles larger than 12×12, including popular wood look porcelain planks in sizes like 6×24 and 6×36. They are durable, and because of their size, fewer are needed per space, meaning fewer grout lines making cleanup and maintenance a breeze. For flooring, accent walls, shower and tub surrounds, countertops, backsplashes, and kitchen islands, large format tiles can help visually expand your space, and create a cohesive feel.

While large format tiles are appealing because they are durable, easy to clean, and come in a wide array of colors and designs, it is important to address installation as these tiles require special handling to insure a professional finish.

Large Format Tiles Must Be Supported Properly

Obviously large format tiles are heavier than smaller tiles. However, what many people fail to realize is that even though the overall weight of the floor remains the same, heavier tiles require a stronger substrate. In addition, with smaller tiles installers may be able to disguise floors that are less than level, but with larger format tiles, that becomes a challenge. A high point in the floor can cause the tile to slope, creating a tripping hazard, as well as being visually disruptive. It is recommended that the variation for 10 feet of horizontal and vertical installation not exceed 1/8 of an inch. When installing large format tiles on a vertical surface, it is important to support the tiles as the mortar sets to ensure gravity doesn’t pull them out of place.

Level Floors & Plumb Walls

For proper installation, floors and other horizontal surfaces need to be level and vertical surfaces must be plumb. Height and depth variations will be noticeable. For floors that are not level, consider using a self-leveling underlayment. As mentioned above, it is important to keep the variation less than 1/8 of an inch. For walls that are not plumb, the walls may need adjustment prior to installation.

Planning the Layout

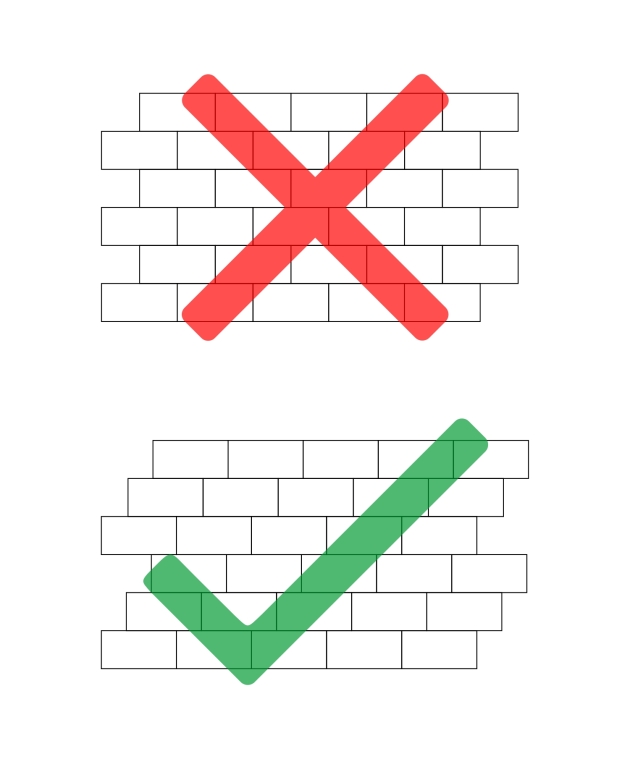

Laying out the tiles prior to installation is important. It helps you to select a pattern that best suits the room. Large format tiles allow for a variety of intriguing patterns including traditional brick patterns, herringbone, straight joint, chevrons, cobblestone, basket weave, and circular rectangular. For plank sized tiles like our Capella Birch Porcelain Tile, it is important to use a 1/3 offset pattern, as shown in the illustration below, instead of a standard 1/2 offset pattern often used for smaller tiles. This helps to prevent cracking and lippage, as well as creates a more beautiful end result.

Choosing Grout

As with all tile floors, the color of the grout needs as much consideration as the tiles themselves. When installing large format tiles and planks, it is vital to adhere to the recommended grout line widths, recommended patterns, and all installation guidelines. For all of rectangular tiles, a minimum of a 1/3 or more off set with 1/8 grout joint size is recommended for rectified tiles and a 3/16 grout joint for non rectified. If you want a more cohesive flow to the room, it is recommended to use grout that is as close to the color of the tile, as possible. This creates a more seamless appearance, and helps to visually expand the room, allowing the beauty of the tiles to shine.

If you love the look of reclaimed wood, but are hesitant about the durability and upkeep required, Salvage Red Porcelain Tile, available in 6×40 planks, is a great option. Planks in these dimensions are perfect to create a traditional wood-look floor when installed in a 1/3 offset pattern. They can also be installed in a herringbone or chevron pattern for additional visual interest. It is highly recommended that you layout a variety of patterns in the room to determine which design best suits the room.

Safeguarding Against Cracking with Proper Mortar

Due to the weight, and the size of large format tiles, it is imperative to use mortars or thin-sets specifically formulated to support the larger tiles. This is important for all installations whether vertical or horizontal. Polymer modified mortars and medium-bed mortars help tiles adhere to walls better, and shrink less keeping tile from moving and cracking. Medium-bed mortars are often used for flooring to help prevent lippage and slumping into the mortar bed. It is important to note that this type of mortar is more difficult to handle, and it is important not to add additional water as this will adversely affect the mortar’s ability to support the tiles.

As more and more large format tiles come to market, more specially designed mortars are developed to support the weight. Some of the new formulations contain microspheres that help to keep tiles level and plumb. When purchasing tile, discuss the various types of mortars available to ensure a beautiful result that will endure decades of wear. Cracking is also a concern with large format tiles if they are not installed as recommended. Shrinkage of the mortar and uneven surfaces are often the cause. Crack isolation membranes help to prevent this problem and are installed directly to the substrate.

Installation of large format tiles may require special handling but their beauty, durability, and low maintenance make them well worth the additional upfront planning and extra time it takes to install them. Browse through our porcelain collection, which includes our large format tiles, for inspiration on how you can transform floors, backsplashes, showers and tubs, and create stunning accent walls to enhance the beauty of your home.

#5 CEMENT TILE INSTALLATION GUIDE:

Please note: This is a guide. Installers who are part of the National Tile Contractors Association with specific skills in handling of Cement Tiles. They should not need an installation guide as this product us over 1,000 years old and is still made the same way.

It takes practice and skill to install. You do not want to be someones practice installation. (Check references).

Efflorescence The Builder Depot Cement Tile have very few problems with efflorescence as we are using a special additive which has the function of reducing efflorescence. However efflorescence is an inherit problem for all cement-based products. It is a natural occurring phenomenon which is harmless and cannot be totally controlled. If you see white marks on tile surface – that is efflorescence which will gradually go away

Color & Sizes. The Builder Depot Encaustic cement tile are produced from natural materials. The production process is tiles even with a pencil because it can leave marks which may be difficult to remove on the surface.

Storage Before Installation. Make sure all tiles are protected whilst waiting for installation. Leave all Secoin Encaustic Cement Tile packed until they are ready to be laid. Do not stack or place Secoin Encaustic Cement Tile in a manner in which they are not intended (such as exposure to sun, rain, humidity,…), this may lead to marking

Tile Surface Protection The Builder Depot Cement Tiles are coated with a sealer in our factory. This coating is to protect the tile surface during transport and storage. However, this coating is NOT strong enough to protect the tile surface from the entry of stain. Therefore, the tiles should be carefully protected during construction to keep the surface without stain. When installing, please keep your hands clean. Do not write symbol on the tiles even with a pencil because it can leave marks which may be difficult to remove on the surface.

Check Before Installation We recommend that you check carefully before installing the tiles. We will not be responsible when the tiles have been cut or installed.

Caution When Using Sealers Always follow the instructions from the sealer suppliers. We suggest that you should use penetrating sealers with high quality and reputation in the market to protect the tile surface. You can coat many layers to protect the tiling floor to be the best. Please try to coat on one tile before coating the entire floor to ensure utilization of appropriate sealers following the requirements. Test the sealer, water should pool on top not absorb into the tile. If it absorbs into the tile, then when grouted so will the grout causing a stain and you will be emailing us with pictures 😦

Please don’t we have covered the sealing issue here. It is a penetrating sealer, if the tile looks perfect before grouting and then changes color after grouting it is pretty simply to isolate the issue. (If you are just reading this for the first time I apologize for the candid answer as by now you maybe a little upset). Please re-direct that anger at your Cement Tile expert installer who has shown you many pictures of his installation of Cement Tile and you have checked his references.

Equipment & Tools These are basic equipment and tools. You may need more tools for doing the installation.

Equipment

- Mixer: Bottom layer material mixer (mixer or hand drill).

- Equipment for dividing gap and checking flatness: With the largest floor area should take the base surface with high flatness and uniformity.

- Tile Cutter: Cutting tile without damages of the edge.

Tools

- Level

- Hand trowel

- Grout float rubber

- Rubber hammer

- Carpenter’s square

- Containers to wet the tiles

- Buckets for mortar

- Sponge

- Sand paper

- Clean rags

- 3-5 m aluminium straight edge

- Tape measure

- Pencil

Installation Process Installing encaustic tiles is a simple process but requires GREAT CARE so as not to damage the surface of tiles and floor tiles to get the best.

Step 1 Preparing the substrate and tiles for flooring.

- Prepare the tiling substrate which is flat and clean.

- Soak tiles in water for about 20 seconds.

- The tiles can be installed on the substrate with mortar or glue. For the best adhesion, apply mortar or adhesive to both the substrate and the back of the tiles

Step 2 Installing the tiles on the substrate.

- Install the first tiles in three different corners of the floor. Stretch cords to determine the tiled surface.

- The tiles are installed by hand and should be done carefully so as not to damage the tiles. Install one row of the tile based on the selected design to review if there is any adjustment before fixed installation.

- The gap between the tiles up to 2-3 mm.

- After placing the tile on the substrate, use hands or a rubber hammer to balance the tile surface. Do not use a normal hammer or similar tools to balance the surface. Check among the tiles that have equal surface height as if mortar or glue has dried, it cannot be adjusted anymore.

- If there is any dirt or mortar or adhesive on the tile surface, please clean the surface immediately. If dropping mortar on the tile is not cleaned immediately, it will cause stain on the tile surface and after that, the cleansing is very difficult.

Step 3 Cleaning the floor surface and applying penetrating sealer at the first time.

- Let the tiles to get firmly fixed on the floor after the mortar dries, then check the tile surface and clean it. If it still has dried mortar on the tile surface, use a knife blade lightly and carefully to not scratch the tile surface. You can also use sand paper grit #320 or #400 to scrub with water. Absolutely NOT use acid or bleach to clean the floor. Wait for the surface is completely dry before proceeding to coat with protective penetrating sealer in the first time.

- Coat a penetrating sealer on the tile before applying grout. The purpose of the first coating is to provide a 1st protective layer to prevent grout stick on the tiles. Wait for the coating to be completely dry (approximately 12-24 hours).

Step 4 Grouting the tiles.

- Applying grout on very thin joint among the tiles. Grout can be white or light colors. Most common grout is white powder. If using color grout, choose the color similar to the tile color. DO NOT use black or dark-color grout because they can cause stain on the tile surface and unable to be removed. Clean the excess grout on the tile surface.

- After installing and applying grout for the tiles, they must be cleaned immediately with water. Do NOT use any cleaning liquids containing acids. For necessary hygiene, you can use a neutral soap.

Step 5 Applying penetrating sealer the second time.

- Leave the tiled floor to be completely dry, then apply protective penetrating sealer for the 2nd time.

Step 6 Protecting the floor after installation and during using process.

- For new construction projects, please cover to protect the surface so that the interior contractors do not damage the floor in the process of finishing the construction.

- In using process, the floor should be covered with protective penetrating sealer periodically, usually every 6-12 months depending on the type of sealer used and the traffic on the floor.

Thank you for choosing The Builder Depot Encaustic Cement Tiles. Hope you will have a beautiful and satisfactory tile floor

Maintenance Guide Please read it carefully before and while using Secoin encaustic cement tiles. Secoin encaustic cement tile is the highly artistic handmade product and need to be maintained properly to keep an enduring beauty.

First Cleaning After Installation

The first cleaning will be performed no sooner than 3 days and no later than 7 days after the finishing the construction and applying protective sealer.

Cleaning The Floor Daily Floor tiles should be wiped and cleaned daily to protect the surface. Do not use chemical cleaners to clean the tile floor. You can use the normal type of floor cleaning liquid not containing acid.

Routine Maintenance Depending on usage, the floor tiles are applied with protective sealers every 6 months to 12 months. Before applying, please comply with guidelines of cleaning process – let the floor dry – apply sealer at 1st time – let it dry – apply in the second time – let it dry.

Removing Stains IMPORTANT NOTE: DO NOT use detergents with strong acids because they will damage the surface of the floor tiles. If there is dirt on the floor (such as tea, coffee, lemon, oil …), you should clean it as soon as possible. If leaving for a long time, stains can penetrate into the floor and will be difficult to remove later. Even if floor tiles are applied penetrating sealer, most of the sealers on the market cannot prevent 100% stain penetration.

Therefore, we recommend that customers should clean the stain within 1-3 hours. A method can be applied to clean stubborn stains and dirt using sandpaper grit size of #320 or #400 to rub stain. When rubbing with sandpaper, you need rub with water. Gently rub then more strongly until you see the stains fade.

Immediately wipe off the dirt for not affecting other parts of the tile surface. After scrubbing the stains, let the floor dry and then apply penetrating protective sealer on the surface.

Cleaning with Special Chemicals In the market, there may be special available stain removing chemicals. However, we recommend that customers should communicate with chemical providers and try on one tile before applying to the floor.

Please unsure you use fully qualified installers. They have qualifications. Check with them. Ask them how he plans to lay it. If he shows you a 50% point of install and not 33%, then he is not certified or has not been on any courses from the Tile Council of North America and I would not use this installer!

To cut the Metal Mosaic square tile can I use my Dremel with a diamond blade? Usually works great for me with porceline or Ceramic?